Training

Training is extremely important for both the employee as well as the organisation the individual is working for. As we provide training with a very technical content, the first goal is to achieve a positive professional impact. However, increasing the knowledge of the one undergoing training is only the beginning of the full potential that can be achieved in all areas:

Knowledge increase may result in more confidence in daily work. It is also very likely to result in sharing newly gained knowledge with others within the organisation.

Given the opportunity to attend a training will make the individual more valued. This will translate into caring for the work and the organisation the individual is working for. The quality of work will continuously excel. A show of commitment can clearly be seen.

Caring means sharing. It will result in helping others and mentoring younger colleagues. This is a true value for the organisation and very difficult to measure quantitively.

As the individual grows professionally, more opportunities will come on to his path. Both within the organisation the individual is working for, as well as outside.

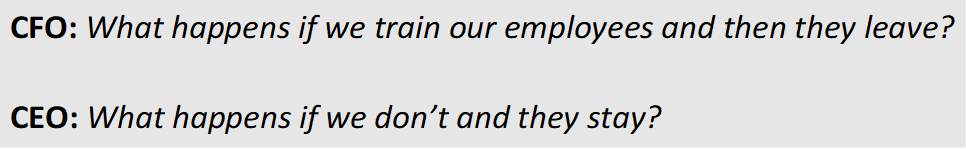

Just something to consider:

Therefore, how can we help with your training needs?

Course 1

Understanding & improving the separation performance of scrubbers & separators

For: Asset managers, engineering managers, process engineers, engineers involved debottlenecking studies, facility engineers & operators at site

Duration: 2 – 4 hours, depending on audience / depth level / scope of training

Notes:

a) This course can be tailored to your needs and actual situations;

b) This course only contains static calculations;

c) This course can be given at any office or (offshore) site of your preference;

d) Group size limit: approx. 20;

e) Optional: CFD simulation can be performed of actual situations (upfront) and used during the course to visualise the actual flow pathlines occurring in your equipment.

Course 2

Detailed calculations to design or debottleneck scrubbers & separators

For: Engineers involved in FEED or debottlenecking studies, facility engineers & operators at site, staff process engineers

Duration: 4 – 6 hours, depending on scope of training

Notes:

a) This course can be tailored to your needs and actual situations;

b) This course may use dynamic calculations;

c) This course can be given at any office or (offshore) site of your preference;

d) Group size limit: 8

e) Optional: CFD simulation can be performed (upfront) of actual situations to visualise the actual flow pathlines occurring in your equipment;

f) This course is available from Q1 2020.

g) Special conditions apply.

As we go forward, specific courses on produced water treatment and sand management will be added.