Consultancy Services

We provide independent consultancy & review studies for upstream oil & gas Clients. From our offices, embedded in Client’s project team or at site. Mostly for brownfield debottlenecking or rejuvenation projects, which may include new-built tie-ins and re-deployment projects.

Obviously, separation is at the heart of the upstream oil & gas process and many issues experienced elsewhere in the facility translate back to the performance of the separator. However, not always. And not always can the performance of the separator be improved to overcome the issues. We therefore take a holistic view from the outset to determine the best solution / or set of solutions for the Client to suit the given constraints to improve the performance of the facility as a whole, or a specific unit operation within.

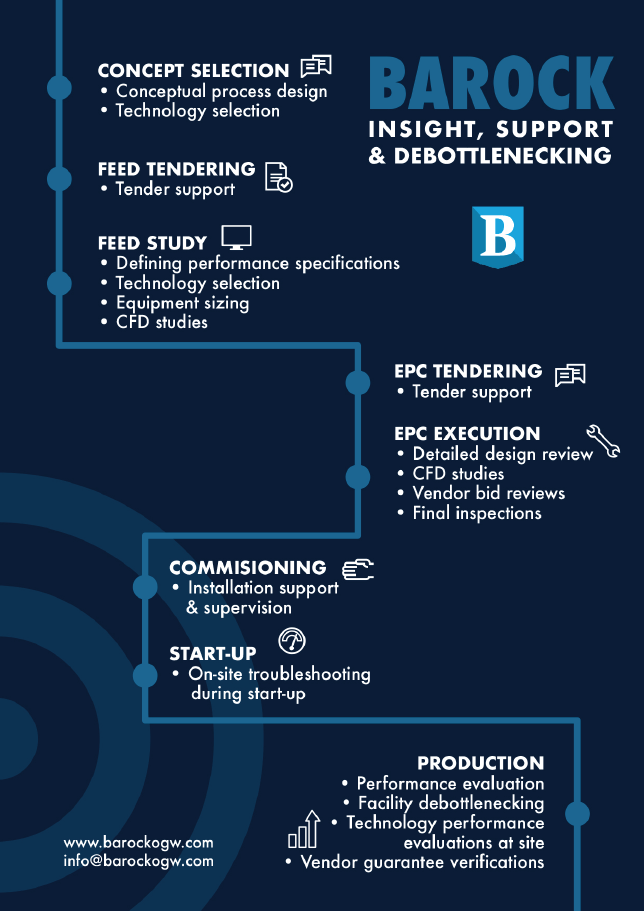

A detailed list of the various services we provide in the various stages from Concept Selection to Production can be found in the sliding menu below. Or simply download the abbreviated electronic mini-brochure to share with collegues.

Computational Fluid Dynamics Simulations

To support our consultancy activities, we have expanded our capabilities to being able to undertake Computational Fluid Dynamics simulations on an in-house basis. This will enable us to be more flexible and cost-effective with respect to offering these services and can incorporate them more easily into larger review studies at shorter notice.

We hold a licence to developing models compatible with the Fluent 2019 simulation software.